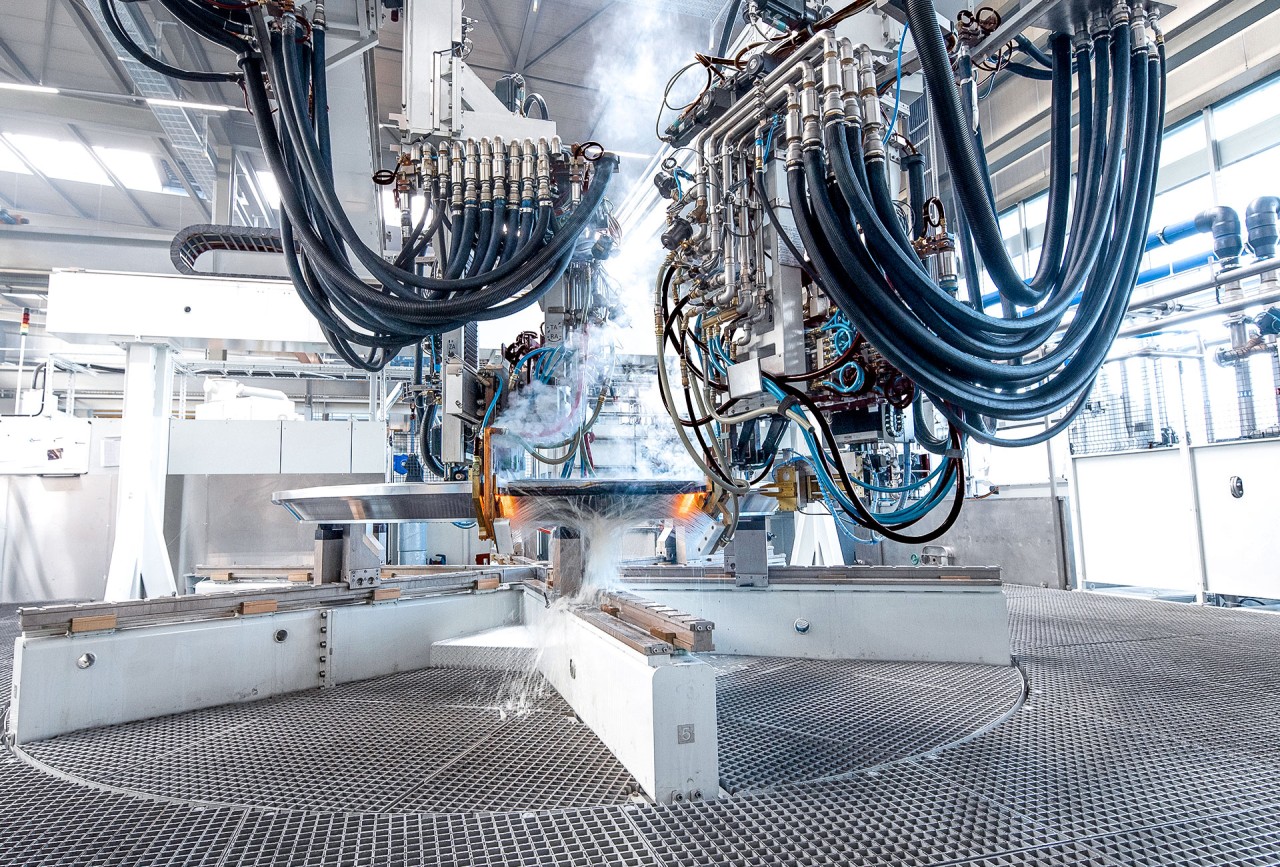

Step by step from ring to slewing bearing: production processes that have it all

Whether harsh environmental conditions, extreme installation situations, heavy loads or high radial and axial forces – slewing bearings must withstand the various environmental conditions, permanently and reliably. Unique production processes ensure that Liebherr slewing bearings are robust and durable in any installation situation.

Large slewing bearings, high vertical integration

Particularly in quality-determining production steps, Liebherr scores with a high level of vertical integration. This ranges from the machining and slip-free induction hardening of bearing raceways, through the gear cutting of slewing bearings, to surface coating in house. Professional know-how and modern machinery characterize the entire manufacturing process.

Slewing bearings in stock

Looking to save time and avoid delivery bottlenecks? Order the right slewing bearings from our stock!

Take a look inside the production halls where a ring becomes a slewing bearing

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).More topics that might be of your interest

Special CX coating: the power lies in the detail

The electric adjustment system, our solution for the wind assisted ship propulsion, benefits from the special CX coating. It ensures that the surface of our slewing bearing remains resistand to seawater.

Lifinity: Solid lubrication

Unlock operational excellence with Lifinity – our advanced solid lubrication for slewing bearings that lasts forever and serves a lifetime!