Be ready for docking!

Your ship must go into dock – think about your cranes as well. With a pre-docking inspection, you are ready for a fast and effective dry-docking.

With a predictive inspection, you only order parts that are required and avoid unplanned delays while your upcoming dry-docking.

Delegate resources and benefit from an even better budget planning and our specialists’ years of experience.

Step 1: Inspection

Four to six months before dry-docking is the time to focus on preparations. Our experienced engineers usually need one day to inspect a crane at a location of your choice worldwide.

- Visual inspection of crane condition

and relevant components - Checking of all electric and electronic configurations

- Monitoring of all hydraulic settings

- Crane function test and rope inspection

- Taking of oil samples for analysis

Step 2: Follow-up

Our engineer will issue your individual follow-up report based on the results of the inspection.

It contains:

- Complete check list

- Inspection report

- Oil sample analysis

- Offer of parts and repair solutions if necessary

- General recommendations

Step 3: Planning and budgeting

We support you in the best possible time and resource management.

Knowing the condition of the crane helps you to avoid unforeseen findings during your dry-docking. A pre-docking inspection gives you the opportunity to avoid unexpected expenses and carefully plan and budget for the eventual work that needs to be done.

Step 4: Condition-based parts delivery and service

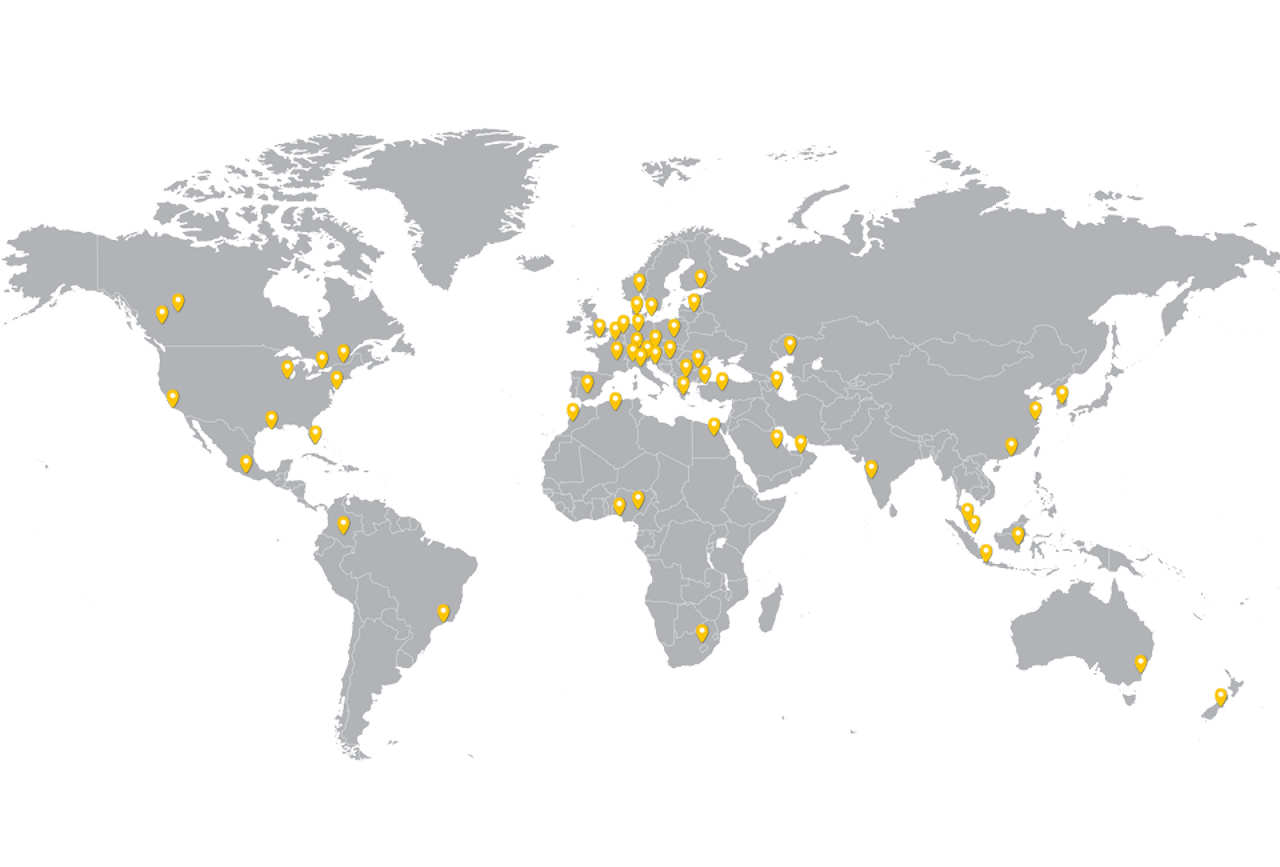

Our global network ensures that all required parts will be available during your dry-docking.

You can decide whether you want them to be delivered to a suitable address before dry-docking or directly to the shipyard.

You have the option that our experienced engineers or other specialists will perform the tasks directly and make your crane fit for new challenges.