Steel-strength power in scrap handling

The handling of scrap steel and other metals is one of the toughest applications in industrial goods handling. Everyday life in a scrap yard is tough, with demanding working conditions characterised by heavy loads, sharp edges and often bulky or long materials. In this environment, safety for both man and machine is extremely important. Liebherr machines not only offer the necessary stability and robustness, but also maximum safety and innovative technologies that optimise the work process in scrap handling. By reliably mastering the tough work processes in scrap yards, they play a key role in the circular economy and help to return valuable resources to the economic cycle. This process plays a key role in conserving additional resources and makes an important contribution to environmental protection.

Requirements in scrap handling

- Machine availability

- Safety

- Sustainability

- Comfort

- Flexibility

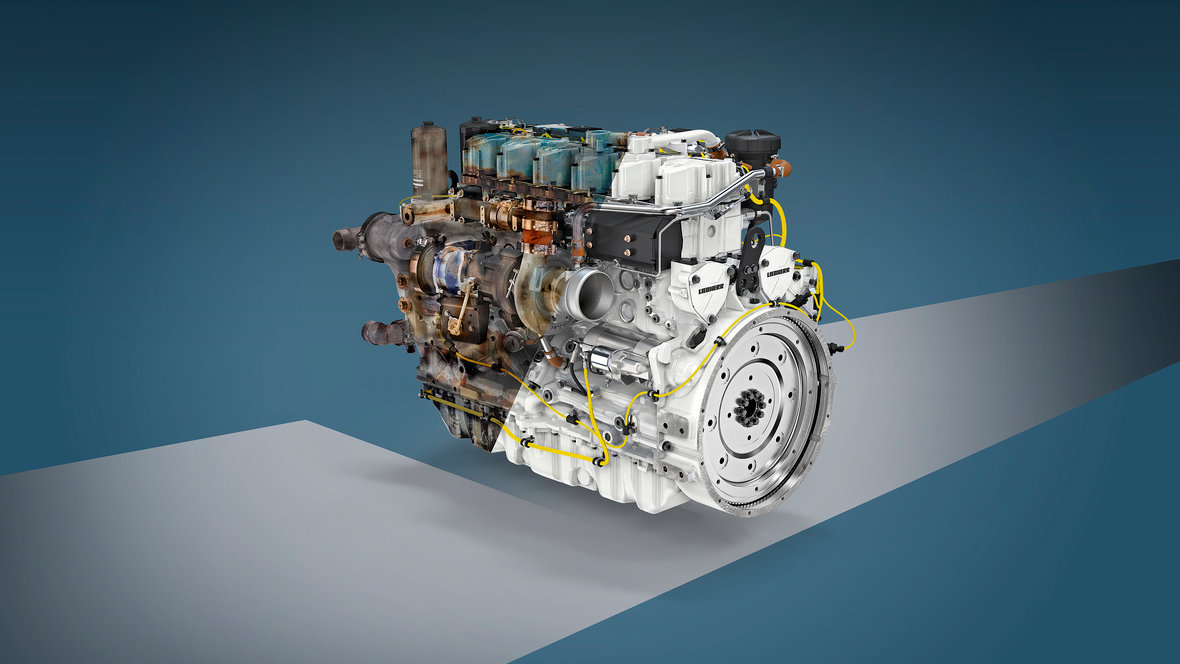

The reliability of the machines is an important factor for a smooth scrap handling process. Handling machines must be designed to be robust and durable in order to avoid expensive downtimes in this industry and to be able to guarantee continuously high performance and maximum machine availability. Low-wear materials, high-strength sheet steel and quality components are essential to guarantee a long service life and reliable operation, even under the toughest operating conditions.

The reliability of the machines is an important factor for a smooth scrap handling process. Handling machines must be designed to be robust and durable in order to avoid expensive downtimes in this industry and to be able to guarantee continuously high performance and maximum machine availability. Low-wear materials, high-strength sheet steel and quality components are essential to guarantee a long service life and reliable operation, even under the toughest operating conditions.

Diverse applications in scrap handling

-web_w1920.jpg)

Transporting and loading

Sorting