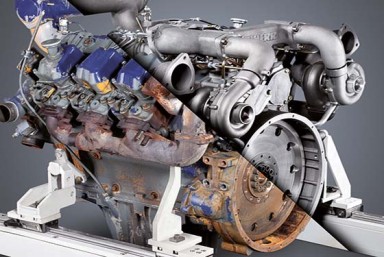

D9612 Construction

Diesel engine

Highlights

The Liebherr diesel engine D9612 with 12 cylinders in-V arrangement and a displacement of 27 liters can achieve a power output of 900 kW at 1800 revolutions. The robust design of the D9612 is built to withstand the harshest conditions of the construction and agriculture industries. This twelve-cylinder engine comes with an integrated centrifugal water pump and closed crankcase ventilation system, ultrafine fiber oil filter, fuel fine filter on engine as well as twin scroll turbocharger that considerably improve fuel consumption. Our engine condition monitoring solution and LiDIA diagnostic tool, together with a long life service further extend reliability and minimize engine down time.

Photo gallery

Downloads

Technical data

| Compression ratio | 15:1 |