Conveying systems: versatile deployment possibilities

For all construction sizes, Liebherr offers a modular system that can be adapted optimally to the respective type of application.

Friction roller conveyor (FRB)

With friction roller conveyors, workpieces can be transported directly or on pallets. Due to the accumulating effect they can be operated indexing independent.

Plastic chain conveyor (KKB)

Plastic chain conveyors from Liebherr are designed to transport any number of irregularly shaped workpieces without them coming into contact with each other. Due to the accumulating effect they can be operated indexing independent.

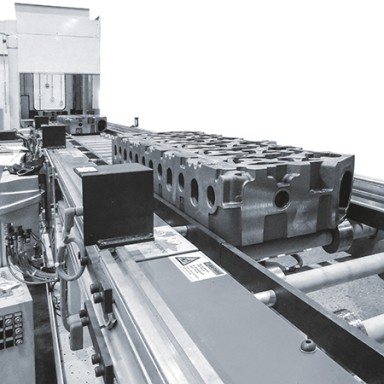

Section roller conveyor (SERB)

Section roller conveyors from Liebherr are used for conveying transport pallets or for direct transport of very heavy components such as truck engine blocks, for example. Due to the linear effect they can also be operated indexing independent