Liebherr automation for flexible manufacturing

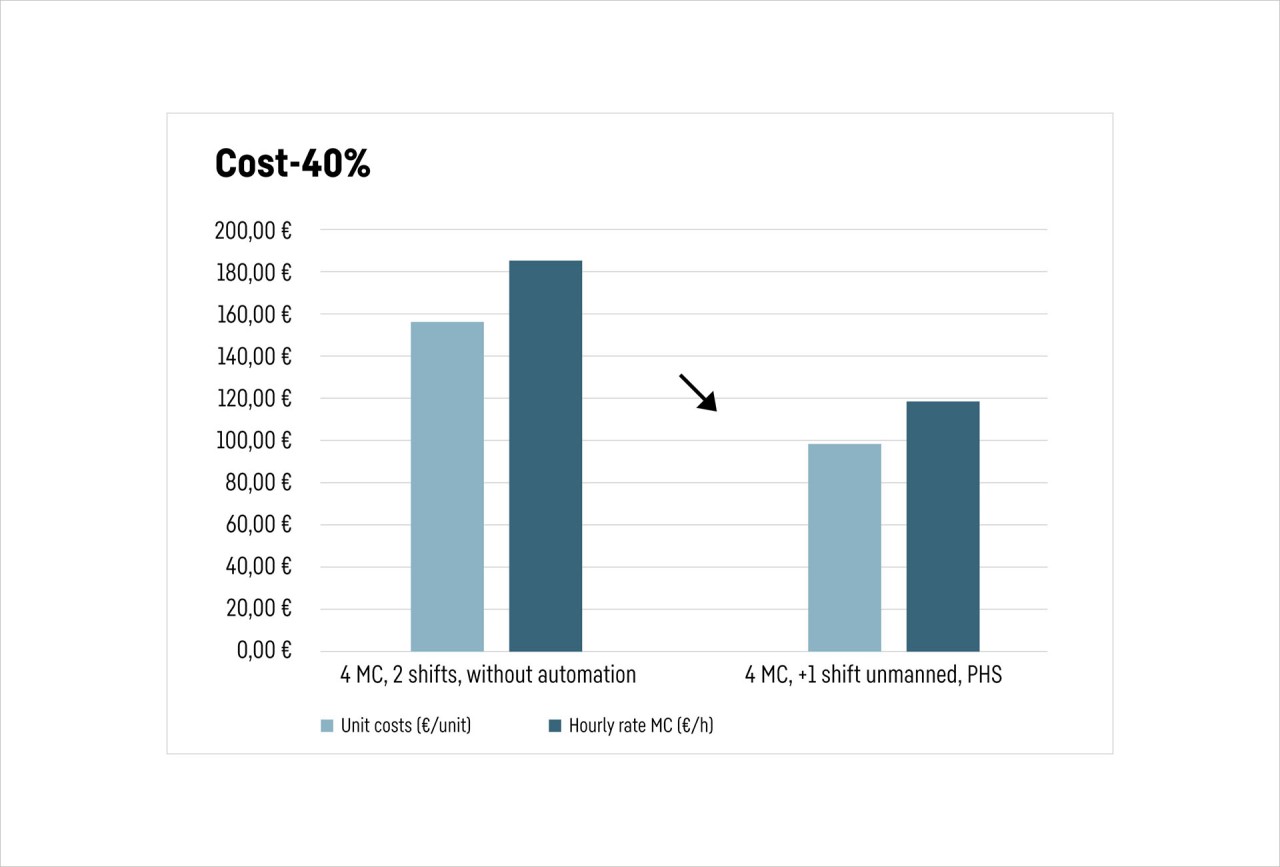

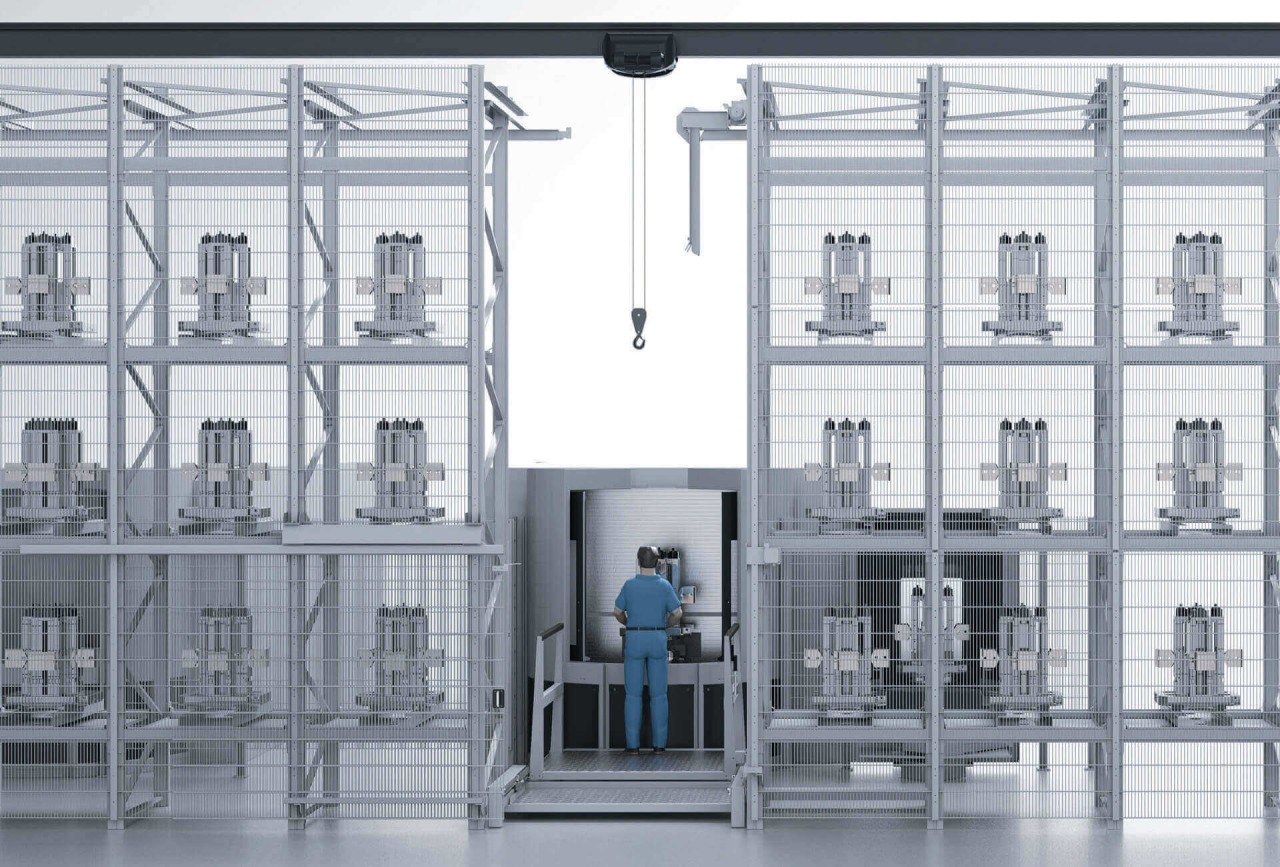

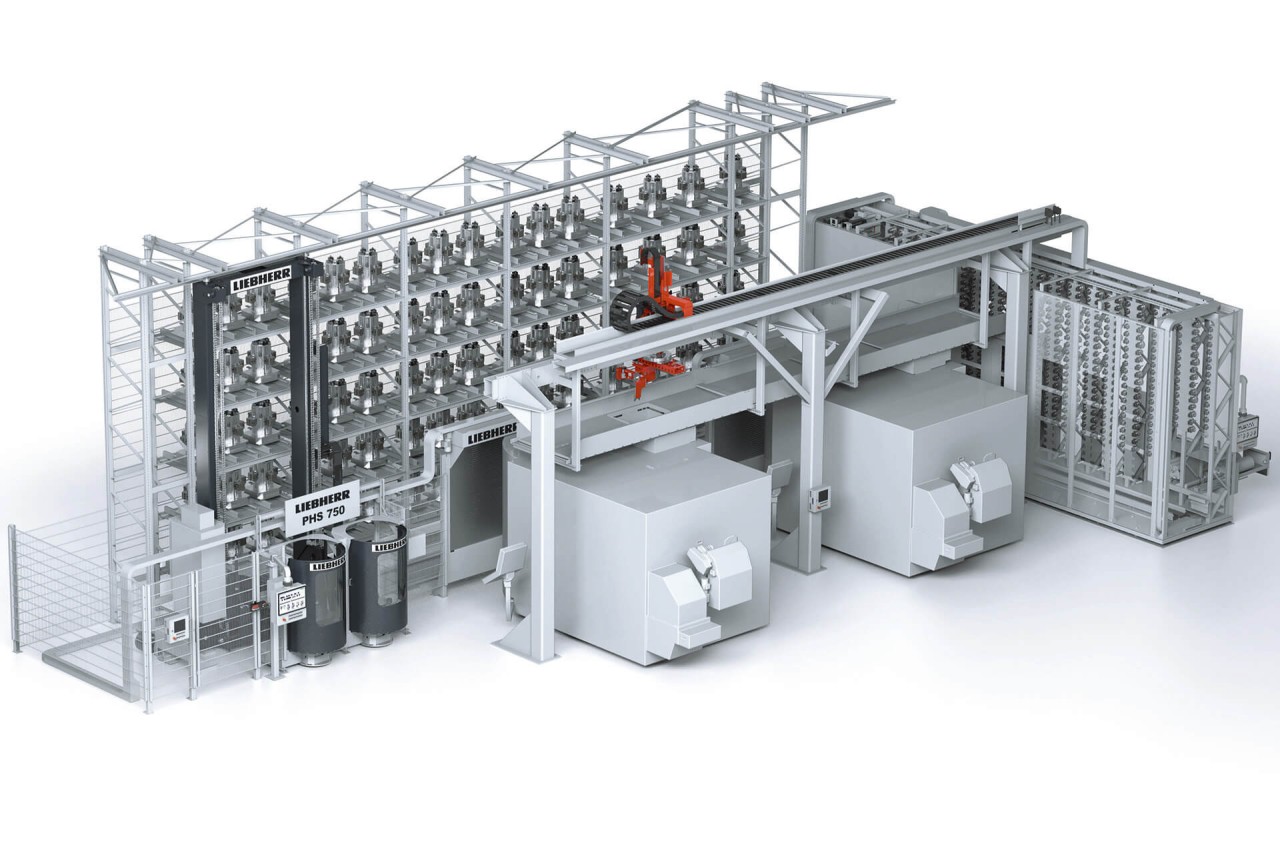

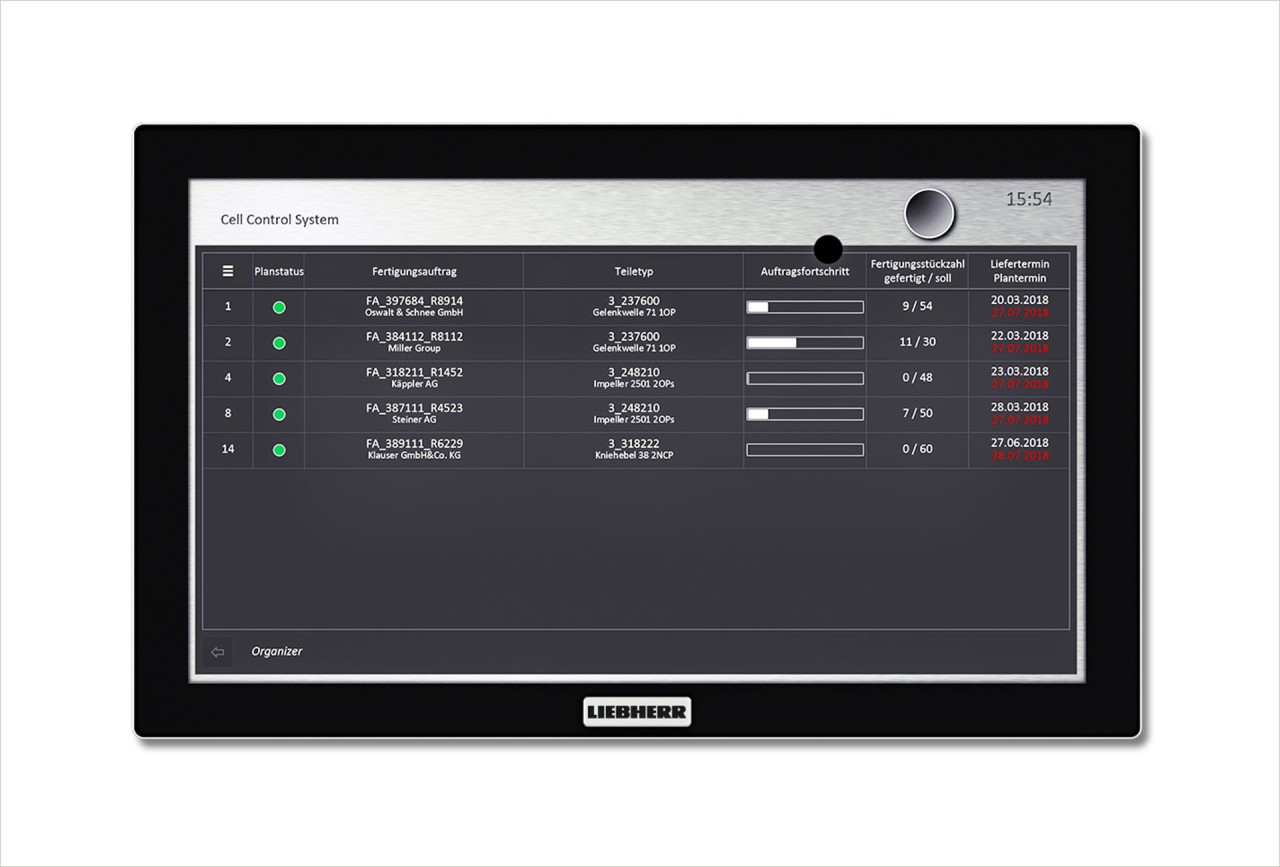

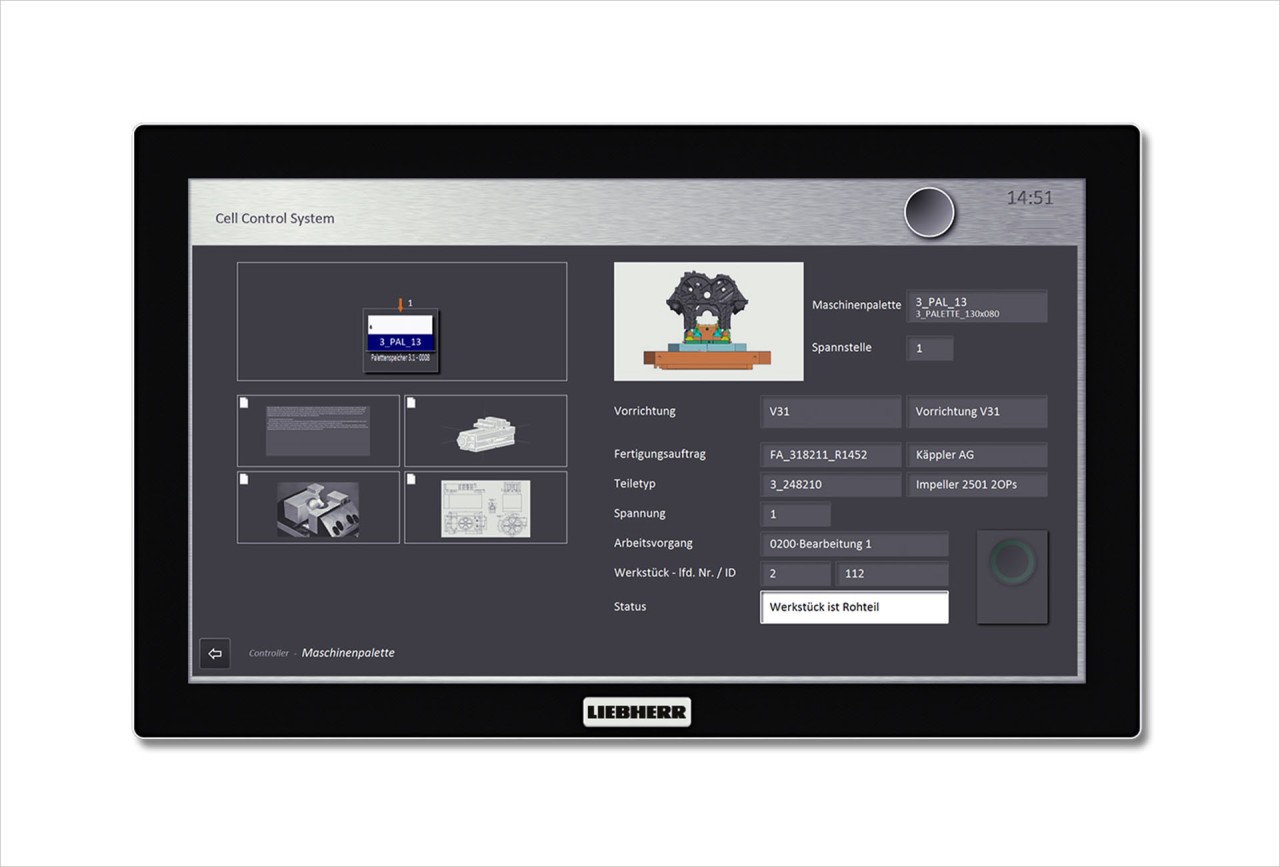

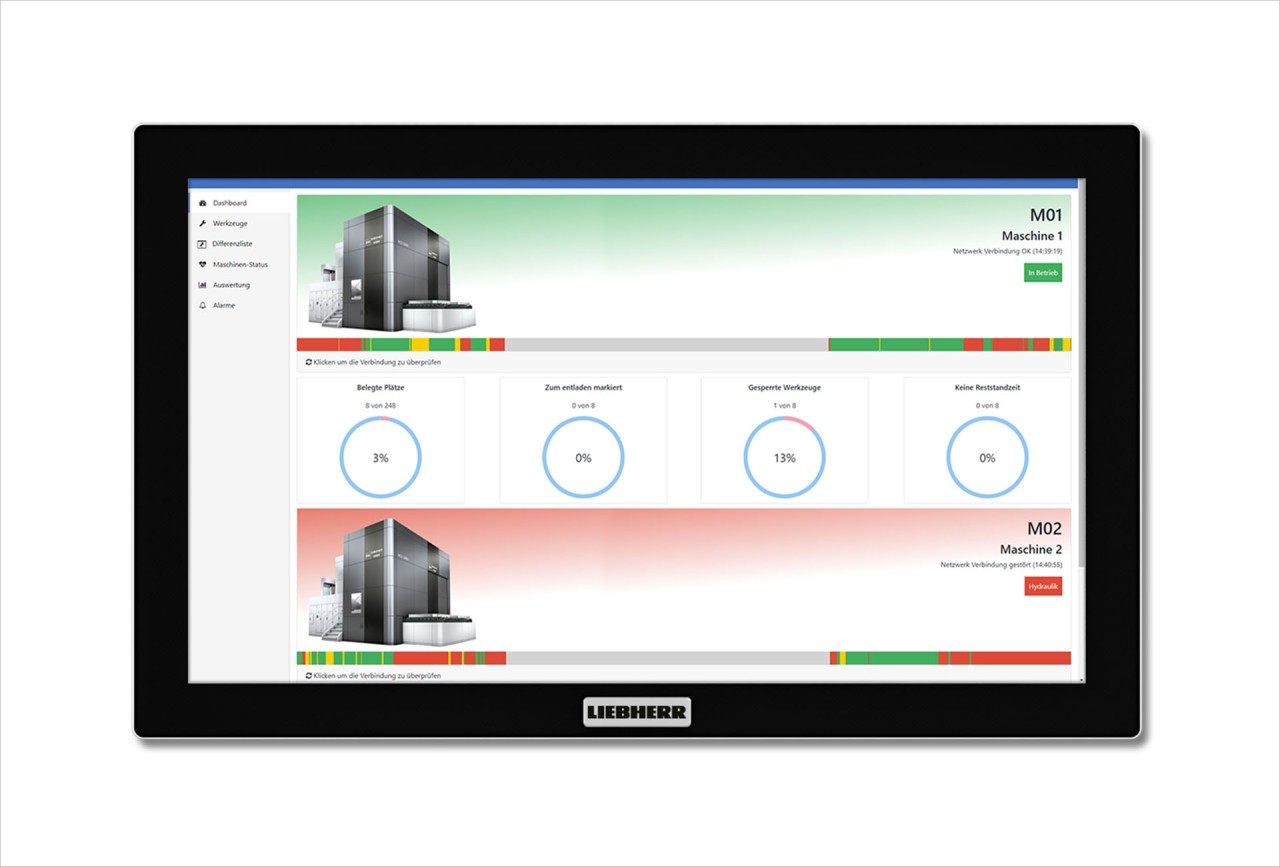

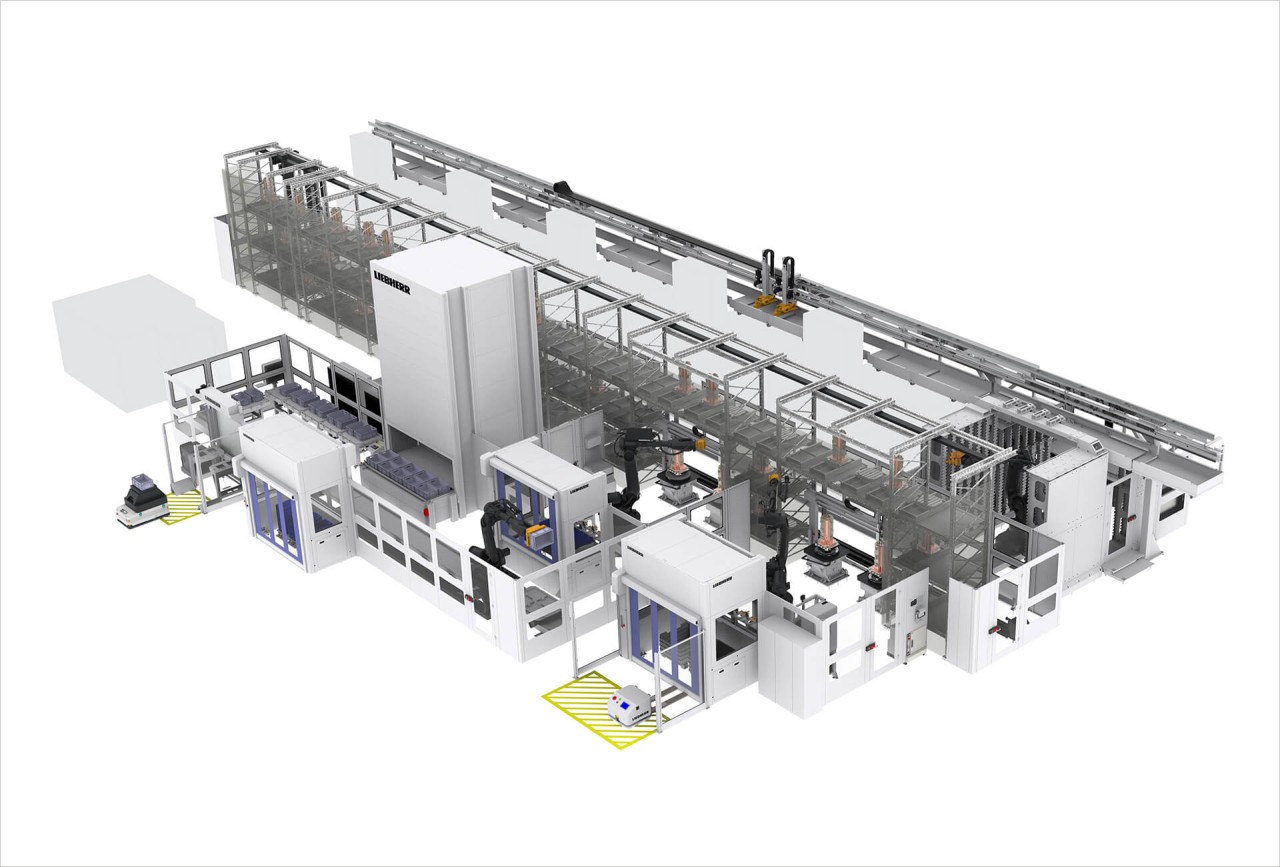

The PHS Pro linear Pallet Handling System leaves nothing to be desired. This product line is flexibly scalable like no other. There is no limit to the length, height or number of machines, even in the heavy-duty range of up to 13 tons of transport weight. This flexible manufacturing system is equipped for large weights as well as small quantities. It automatically delivers machine pallets to machine tools. The pallet handling system increases the machine runtime utlization to up to 90% and reduces unit costs by up to 40%.

Product highlights of the PHS Pro:

Have we sparked your interest? Here's where you can find more information about our products:

Results 1–2 of 4

1

2

Find out more about our PHS Pro

Read an exciting article from our customer brochure