Horizontal concrete batching plants - LCM series

Robust, reliable, durable

The LCM concrete batching plant series has a simple but robust design. The assemblies are optimised for cost-effective transport and quick assembly. A modern and easy-to-operate control system rounds off the attractive overall package.

Modern technology at an affordable price.

LCM 1.0

Economical mixing plant with unique advantages

The LCM 1.0 concrete mixing plant combines solid construction, cost-effective transport and assembly with an attractive price/performance ratio.

A wide variety of concrete recipes are produced reliably and in high quality. The plant is equipped with a powerful ring-pan mixer and produces up to 69 m³ of fresh concrete per hour. The entire concept is designed for high efficiency and a long service life.

Modern technology at an affordable price.

- Various mixer options for customised requirements

- Efficient aggregate storage in an in-line silo

- Modern control system

Please contact our specialists via the contact form for more information about the advantages of the LCM series:

LCM 1.0 video

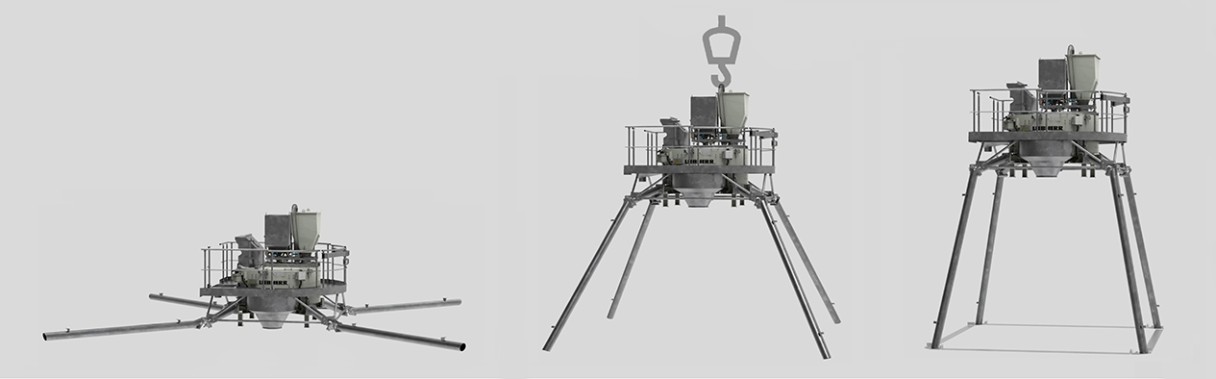

Cost-effective transport and mobile plant concept

The LCM 1.0 concrete mixing plant, designed for economical concrete production, enables simple, fast and cost-effective transport in 2 x 40ft. HC containers. Thus, the concrete mixing plant guarantees a high degree of mobility and offers the possibility of an uncomplicated and prompt relocation of the plant.

Cost-effective transport - Time-saving assembly - Mobile plant concept - Quick and easy assembly

Cost-effective and modern control system

The Litronic-BCS 3 is a fully automatic, real-time control system with extensive features.

All standard tasks as well as data management can be performed conveniently. The simple operation of the control system via two monitors allows the operator to manage master data and visualise the process sequence in parallel. The visualisation components can be freely adapted.

In addition, the system has automatic safety monitoring. Manual intervention is thus possible at any time during the automatic runtime.

Competence in mixing technology

The LCM 1.0 is equipped with an efficient Liebherr ring-pan mixer. In addition, sophisticated mixing tasks can be solved quickly and easily by using an agitator system, if required.

- Ring-pan mixer type R 1.0

- Intensive ring-pan mixer with agitator type RIM 1.0-M

Download

Learn more about our concrete mixing plant LCM 1.0 in our brochure.

LCM 3.0

A masterpiece in it‘s class: Affordable, reliable and flexible

The new Liebherr LCM 3.0 offers a wide range of flexibility as an affordable and economic solution. The plant produces up to 171 m³ of fresh compacted concrete per hour.

German engineering of the innovative LCM 3.0 connects reliability, simple operation and easy maintenance. The LCM 3.0 concrete batching plant convinces therefore by its simple but robust design. In addition, the components are optimised for cost-effective transportation. Modern technology at an affordable price.

Please contact our specialists via the contact form for more information about the advantages of the LCM series:

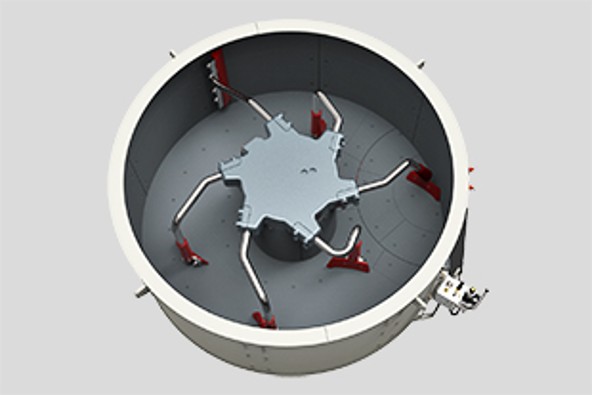

Twin-shaft mixer DW 3.0

- Liebherr twin-shaft mixer for economical concrete production thanks to high mixing quality and short mixing times

- Excellent mixing results can be realized in a short period

- Good accessibility for easy maintenance operations

Galvanized elements for a long service life

- Galvanized finishing of the plant guarantees long time of usage

- High quality standards and a long service life of the plant with only minimal service requirements

Affordable and modern control system

- Fully automatic, real-time capable control system with extensive features

- Easy operation via two monitors

- Visualisation components can be freely adapted

- Automatic safety monitoring for manual intervention during the automatic runtime

Download

Learn more about our concrete mixing plant LCM 3.0 in our brochure.