Fossil raw materials/petrochemistry

Liebherr has been developing measurement systems for industrial automation since 1985. Our sensors reliably determine the moisture in various materials. The benefit of Liebherr measurement systems is high precision thanks to 40 measurements per second, as well as the sensors' reproducibility.

Moisture and water content determination

Liebherr has been developing measurement systems for industrial automation since 1985. Our sensors reliably determine the moisture or water content in various materials and liquids. The benefit of Liebherr measurement systems is high precision thanks to 40 measurements per second, as well as the sensors' reproducibility. The systems can be integrated in various production facilities such as on conveyor belts, upstream and downstream of dryers, at transfer points, in hoppers but also in pipelines or tanks. Our systems measure, monitor and regulate the humidity or water content automatically and in real time. Continuous measurement guarantees high precision.

Sensors are developed and manufactured at the Liebherr-Mischtechnik GmbH location in Bad Schussenried (Germany). Here, we produce and calibrate the sensors in an environment protected against ESD.

Sensor manufacturing in Bad Schussenried (Germany)

Reliability that promotes trust

We test each sensor over the entire working temperature range in a process that takes several hours.

When Liebherr started producing sensors, we used the measurement systems that we developed ourselves only in our own concrete mixing plants. The sensors determine the sand moisture in the running process. For this task, we developed sensors that work reliably even under extreme outdoor conditions. Our experience in concrete technology pays off for our customers: Liebherr sensors measure precisely and have a long service life.

Examples of uses for fossil raw materials/petrochemistry

Products

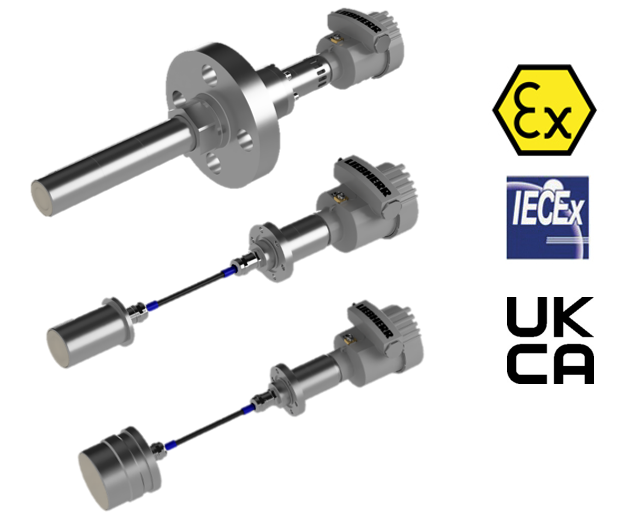

These products are available for applications in the field of fossil raw materials and petrochemistry.

Litronic FMS RMH12

The pipe sensor was specially developed for determining the smallest amounts of water (trace moisture) in liquids. The sensor in conjunction with the FMS III evaluation and transfer unit is used, for example, in test and trial systems for monitoring the water separation ability in diesel fuel filters.

Litronic FMS II Evaluation and transfer module

The modular design allows networking of up to 16 sensors on one evaluation unit. Extensive signal processing options for transfer to a higher-level control and the exact and fast calibration of the measured sections are just some of the many advantages.

Further information and downloads

You can select the corresponding products here. Click to go to the corresponding product page

We will be happy to send you the relevant job reports on request.

- Petrochemistry: Crude oil, diesel, biodiesel, hardening oil, fuels, coolants, lubricants

- Building materials industry: Ores, minerals, dusts, slag, ceramic powder, coal, coke, mineral, aluminium granulate, sludges

Litronic WMS

Questionnaires

Sales contact person

Service contact person