Electronics

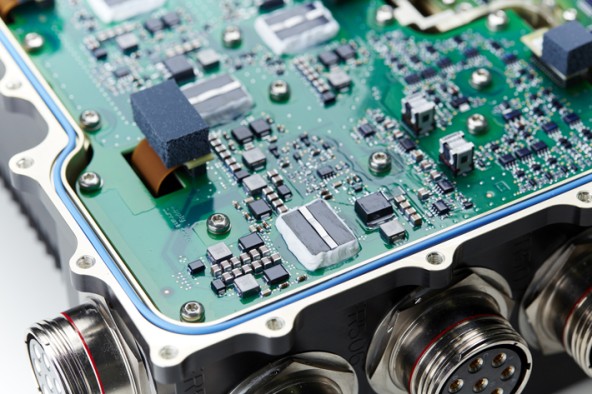

Liebherr has acquired an unrivalled experience in designing on-board electronics for the control and monitoring of highly integrated, flight-safety critical and complex systems.

For over 30 years, more than 20,000 electronic units designed and manufactured by Liebherr have demonstrated their outstanding in-service reliability on board commercial and military aircraft, helicopters as well as business jets in ATA chapters such as ATA 21, 30, 36 (air management, ice protection, pneumatics), ATA 24 (electrical power), ATA 27 (flight controls), and ATA 32 (landing gear).

Liebherr supplies these electronic units with embedded software, both as standalone units, or as part of the company's air management, flight control and landing gear systems. In terms of hardware development, qualification and production for signal and power circuits, Liebherr-Aerospace benefits from the Liebherr Group’s competence center for electronics in Lindau (Germany).

The world class standalone electronic products developed by Liebherr as an integral part of a flight control, air management or landing gear system can also be applied for multiple other applications on an aircraft. Different ATA chapters as for example power or equipment/furnishing can also benefit from the tremendous Liebherr expertise in power and signal electronics.

Static inverter

Liebherr develops static inverters, which offer a reliable, lightweight, fully digital solution. They are based on wide band-gap technology together with enhanced connection functions.

Main product features:

- 120 VAC 60Hz single phase, 115 VAC 400Hz single phase (emergency)

- Comprehensive power conversion range (from 100 W to 2 kW)

- Internal monitoring and protection

- Digital control and communication : smart/tunable monitoring and protection capability

- Fanless design up to 500 VA: lightweight, reliable (200 kOH), competitive

- TSO/ETSO certification

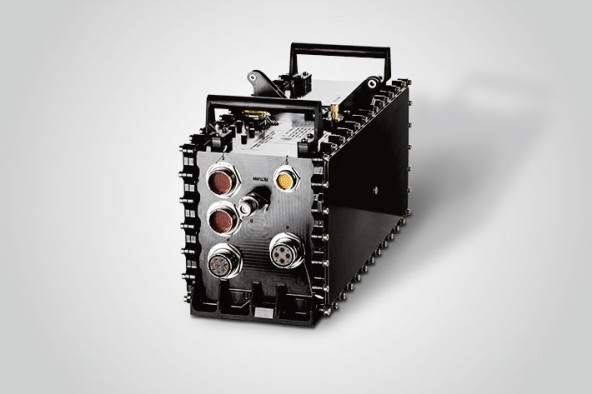

Generic purpose REU

Another example is the generic purpose REU: A universal remote electronics for different AC applications.

- Safety critical applications in unpressurized areas

- Adaptable aircraft interfaces and attachments

- Universal and configurable analogue inputs and outputs for different interface evaluation

- System independent actuation control and cockpit controls evaluation

Video : An Extremely Versatile Control Unit

Power electronics for the supplemental cooling system on board the A380

Power Electronics

Liebherr’s power electronics and electrical drives are integrated into highly engineered equipment such as electro-hydraulic actuators (EHA), electro-mechanical actuators (EMA), electrical backup hydraulic actuators (EBHA), high power high-speed electrical compressors, electrical air conditioning packs, electrically-driven pumps, and electrical landing gear retraction actuators.

Control monitoring electronics

Signal Electronics

Liebherr’s signal electronics have demonstrated their ability to fulfill the highest criticality missions when so requested by the aircraft manufacturers, like for example for primary flight control computers or for engine bleed air computers.

The control software can be hosted by dedicated controllers designed and manufactured by Liebherr or by IMA modules as selected by the aircraft manufacturer.

Video : Liebherr-Aerospace Electronics

Contacts

Development life cycle for power electronics, digital drive control, electrical motors

- High performance E-Drives

- Calculation and simulation of drive systems

- Model-based development of digital drive control algorithms

- Electrical drives test center

Activities according to RTCA DO254 for safety critical DAL A-D applications

- Requirements capture

- Conceptual design / SRU concept

- Detailed circuit design / Circuit design simulation

- Circuit design analysis (tolerances, de-rating, timing, level)

- PCB design / Layout (component placement and routing)

- Mechanical / Thermal design (open or sealed housing)

- Mechanical design analysis (structure, fatigue, tolerance)

- Thermal design analysis

- Commissioning / Engineering tests (maturity, robustness, environmental)

- Verification of electronic equipment according to RTCA DO 160x and others

- AGILE project management

- Synchronous product and process development with enclosed stage-gate-process

Development and qualification of complex software applications and programmable logic devices

- Safety-critical software development tasks (DAL A-D) according to RTCA/DO178x

- From board support package development to complete software systems

- Software platform development

- Software application development

- Model-based software development

- Software verification and HW/SW integration

- PLD development and verification RTCA/DO-254 (EUROCAE/ED-80)

- Project Management

Engineering

Development of complex electronic systems

- Architecture definition (safety critical)

- System interface definition

- Requirement-based engineering (ARP4754A)

- Model-based system engineering

- Simulation and modelling

- Electronic safety assessment (ARP4761)

- Electronic unit verification

- Engineering/ Robustness testing

- Project management

Test center at Liebherr-Electronics and Drives GmbH in Lindau

- EMC test chamber for:

- radiated susceptibility

- conducted susceptibility

- radiated emissions and

- conducted emissions

- 3 axis vibration shakers with superimposed temperature

- Temperature and humidity test chambers

- Salt test chamber

- HALT test chamber

- Infrared thermal analysis equipment

- Lightning test / ESD / voltage transients generators

Video : Liebherr-Aerospace Electronics

Contacts

Assembly at Liebherr-Elektronik GmbH in Lindau

In-house Manufacturing

Liebherr-Electronics and Drives GmbH in Lindau (Germany) processes more than 100 million of SMD components and produces close to 220,000 PCB assemblies as well as more than 120,000 complete electronic units per year on a total area of 7,200m2.