8 minutes reading time

In the middle of the construction site of the century

Grand Paris is a massive infrastructure project that aims to better connect the capital of France to the outer suburbs, boost economic growth and prevent traffic gridlock at the same time. Right in the middle of the action: Liebherr construction machinery.

Highlights

• In 2016, the French capital was merged with its surrounding départements to form the administrative unit "Metropole du Grand Paris".

• With 22,000 inhabitants per square kilometre, Paris is the most densely populated major city in Europe.

• After the opening of the new Métro lines, the metro network will be the largest in Europe.

• All major motorways and railway lines in France lead to Paris.

• Completion of the construction project is planned for 2030

From Paris to Grand Paris

Around one in five French people live in the Paris metropolitan area, making the city of 10 million inhabitants a huge metropolitan region. A region that is currently trying to modernise its infrastructurebecause Paris is on the brink of a collapse of transport systems. The "Grand Paris Express" - one of the largest and most expensive infrastructure projects in Europe with a construction cost of around 35 billion euros - is intended to remedy this situation. Six new underground lines and 68 stations are to make underground travel faster and thus more attractive. Because of the centralised network, Parisians can currently only get from one suburb to another via the city centre. Even a few kilometres as the crow flies can result in journey times of over an hour.

A total of 200 kilometres of new metro line are to be built. For comparison: The current network consists of 400 kilometres. After the opening of the lines, the Paris Métro will be the largest in Europe. So far, it ranks fourth behind London, Moscow and Madrid.

“Grand Paris" was launched in 2007 by the then head of state Nicolas Sarkozy, who wanted to catapult the capital into the top league of major global cities.

Liebherr construction machines at the Grand Paris jobsite

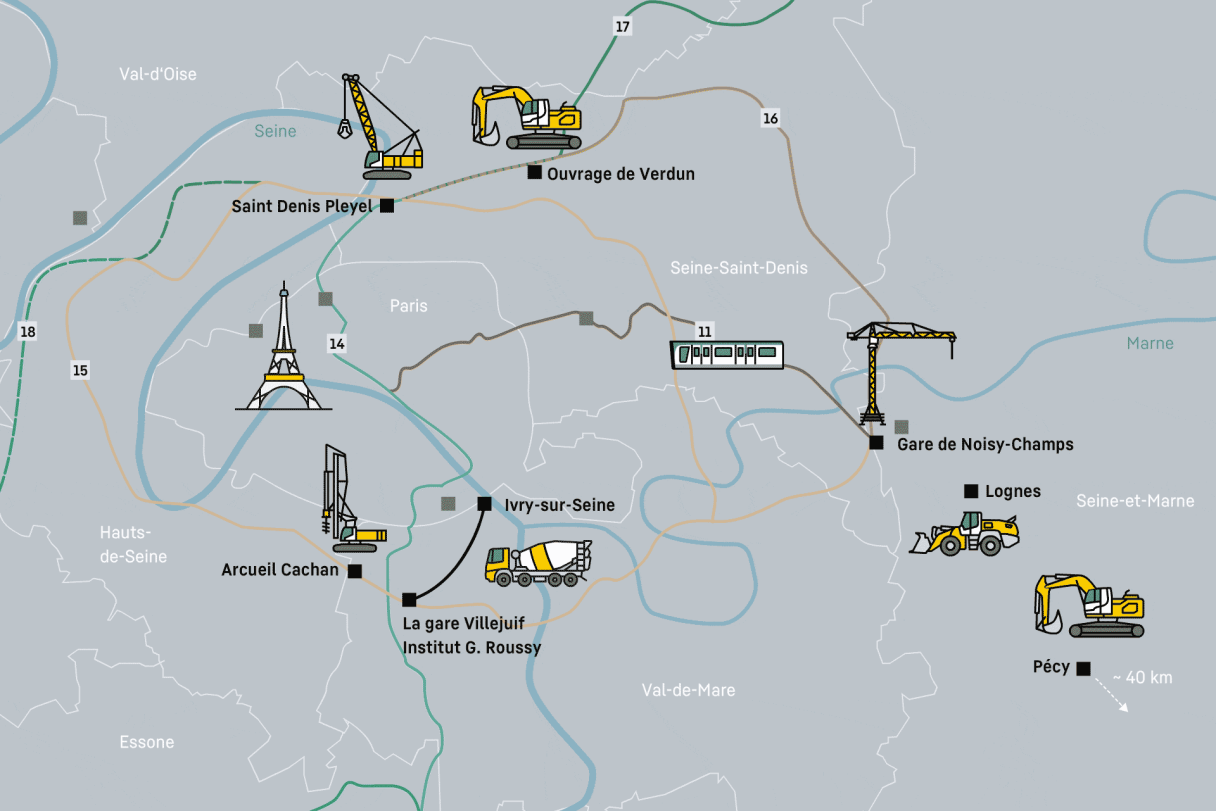

Liebherr construction machines are working at a total of 13 locations on the construction site of the century. They mine bulk material, mix and transport concrete or carry out lifting work.

Grey: completed construction projects | Black: ongoing construction projects

Saint Denis Pleyel

Since April 2018, two Liebherr crawler cranes from Capocci have been working in the northern part of the Grand Paris construction site at the future Saint-Denis-Pleyel Métro station on line 16. The HS 8050 and HS 8070 were purchased specifically for this project to bring bulk material up from a depth of 40 metres. Equipped with a grab weighing almost 10 tonnes, the duo transports a proud 2,000 tonnes of rubble in an 8-hour shift.

La Gare Villejuif Institut Gustave Roussy

The Institut Gustave Roussy station will connect two lines of the future Grand Paris network: line 15 South and the southern extension of line 14. It will be the first port of call for more than 19,000 residents living within a one-kilometre radius of the station and is expected to carry around 100,000 travellers per day from 2025. The HTM 905 gas-powered truck mixer delivers the concrete produced in the Liebherr mixing plants in Ivry-sur-Seine to various construction sites within the Grand Paris project. In total, it can transport eight cubic metres instead of the usual seven, which ensures faster service and fewer trips.

Ouvrage de Verdun

In spring 2018, construction of a tunnel boring machine exit shaft began near the current Le Bourget metro station. It houses the equipment for digging the underground shafts and is the starting point for three tunnel boring machines. To remove the excavated material as quickly as possible, Capocci uses a customised Liebherr crawler excavator. The basis is the R 956, which was equipped with a five-metre-long grab arm and a 2m3 clamshell bucket. After completion of the work, the evaporation shaft will be used as a service centre for ventilation as well as an emergency access to the tunnel.

Pécy

The limestone quarry of A2C Granulat supplies some of the building materials for the Grand Paris project - quarried by the crawler excavators R 970 SME Litronic and R 938 Litronic, among others.

Transport within the quarry is handled by the L 586 XPower wheel loader acquired in 2018. It consumes up to eight litres less petrol per hour - which corresponds to a saving of 25 to 30 percent.

Arcueil Cachan

The LB 16 unplugged drilling rig is making an important contribution to the environment during the construction work on Line 15. It is the world's first rotary drilling rig that is battery-powered and delivers the same performance as a conventional drive. For the construction of a ventilation system, it uses support piles with a diameter of 800 millimetres and a depth of between 13 and 15 metres. Especially in the middle of the big city, it is important to reduce noise and emissions, to which LB 16 makes an important contribution.

Lognes

Béton Solution Mobiles has a total of 15 of the L 546 and L 550 Liebherr wheel loaders in operation. The Paris-based company supplies the Grand Paris construction site with ready-mixed concrete. Among other things, this will provide for the construction work on lines 14, 15, 16, 17 and 18. Some of the 150 employees there work 24 hours a day, six days a week. To do this, they need reliable machines and responsive customer service - which is why they have chosen Liebherr products

Gare de Noisy-Champs

The Noisy Champs station is the place to be. The Liebherr High-Top 1000 EC-H 40 Litronic cranes can lift up to 40 tonnes and are therefore ideally suited for lifting work on the Grand Paris construction site – for example, lifting heavy equipment such as earthmoving machinery or building the metal vault of the metro station.